AUTO ASSEMBLY AND PROCESSES

At UPG Electrical, we pride ourselves in developing unique solutions to tackle tough manufacturing challenges. We have a deep background and history producing automation equipment and systems to solve problems. We design creative and efficient new assembly processes to maximize output and reduce costs, while ensuring uncompromising quality is built into the automation systems and processes. Vision systems are incorporated into the assembly automation to provide real time 100% inspection of critical characteristics. Our manufacturing and engineering expertise is a perfect marriage to design the optimum assembly equipment and process, and then run the production flawlessly for our customers.

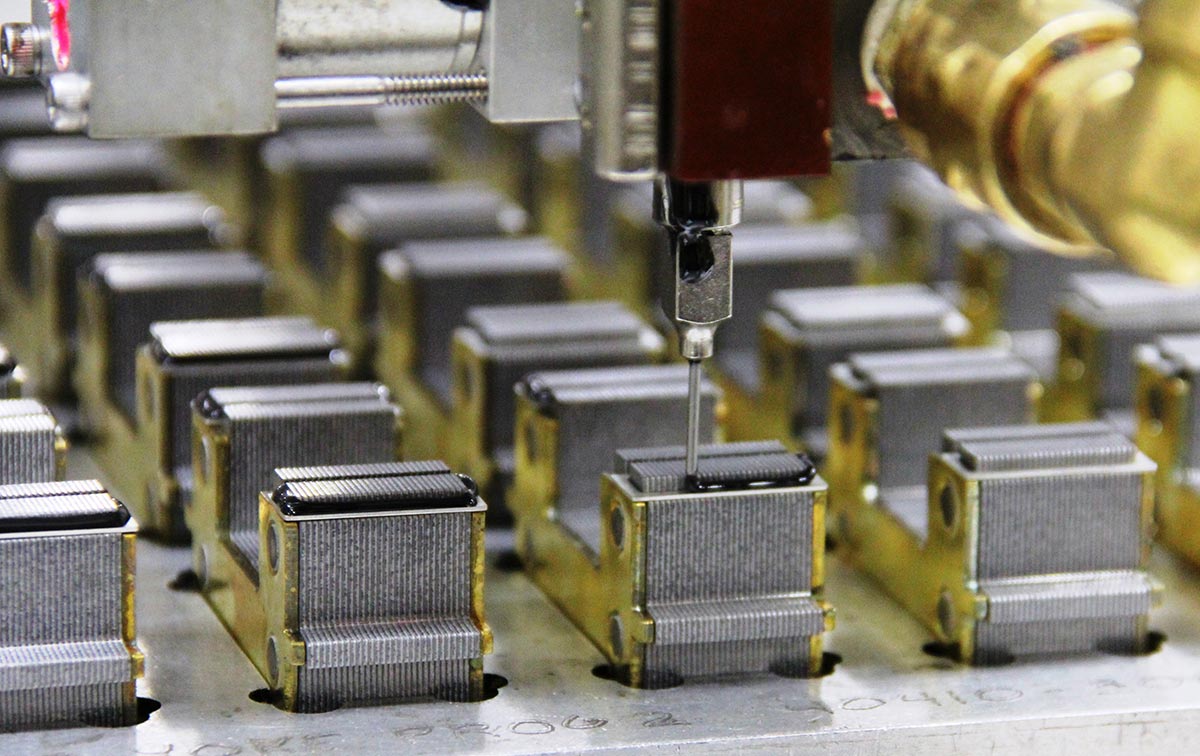

UPG Electrical produces complete motor, generator and transformer cores for our customers. The core building assembly process can utilize interlocking, welding, bonding, fastening, or a combination of many processes. For very large cores, UPG Electrical produces segmented laminations and then completes the assembly of either the segments or the entire core utilizing high precision fixtures and automation. For example, UPG Electrical produces large segments for 14-foot diameter, 2-Megawatt wind turbine generators.